A WELL-ORGANISED PRODUCTION PROCESS

VARESINA STAMPI’S organised production structure allows it to completely satisfy the customer's needs. Starting with the design of the dies, continuing with their production, and then readying them for manufacturing the parts by hot steel drop forging. This is followed by heat treatment, carried out in it's super-specialised in-house department. If necessary, and if requested by the customer, it is then possible to carry out final machining to complete the production process.

DISCOVER THE STAGES OF THE PRODUCTION

>>>>

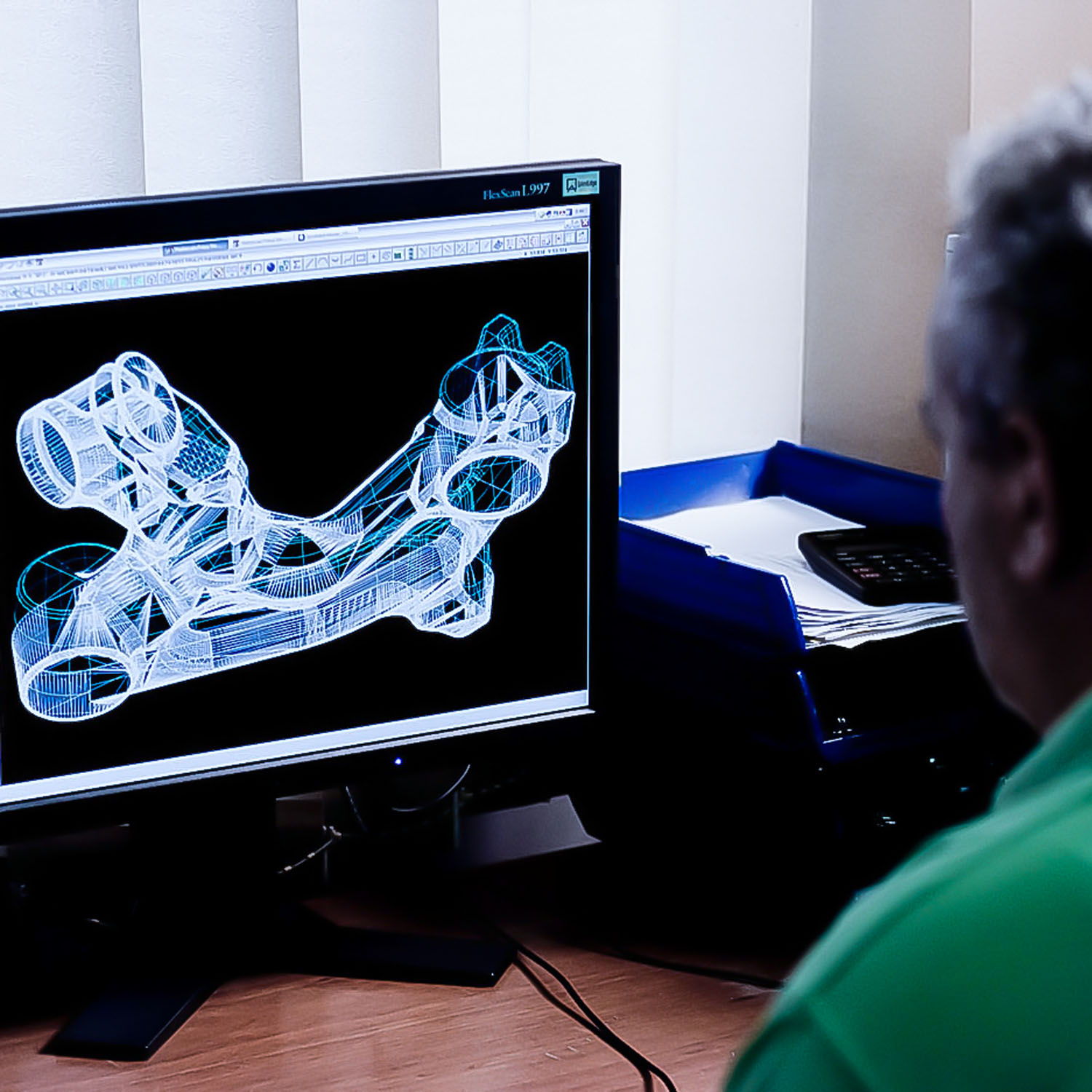

Dies Design

CAD systems and hot steel stamping simulation

>>>>

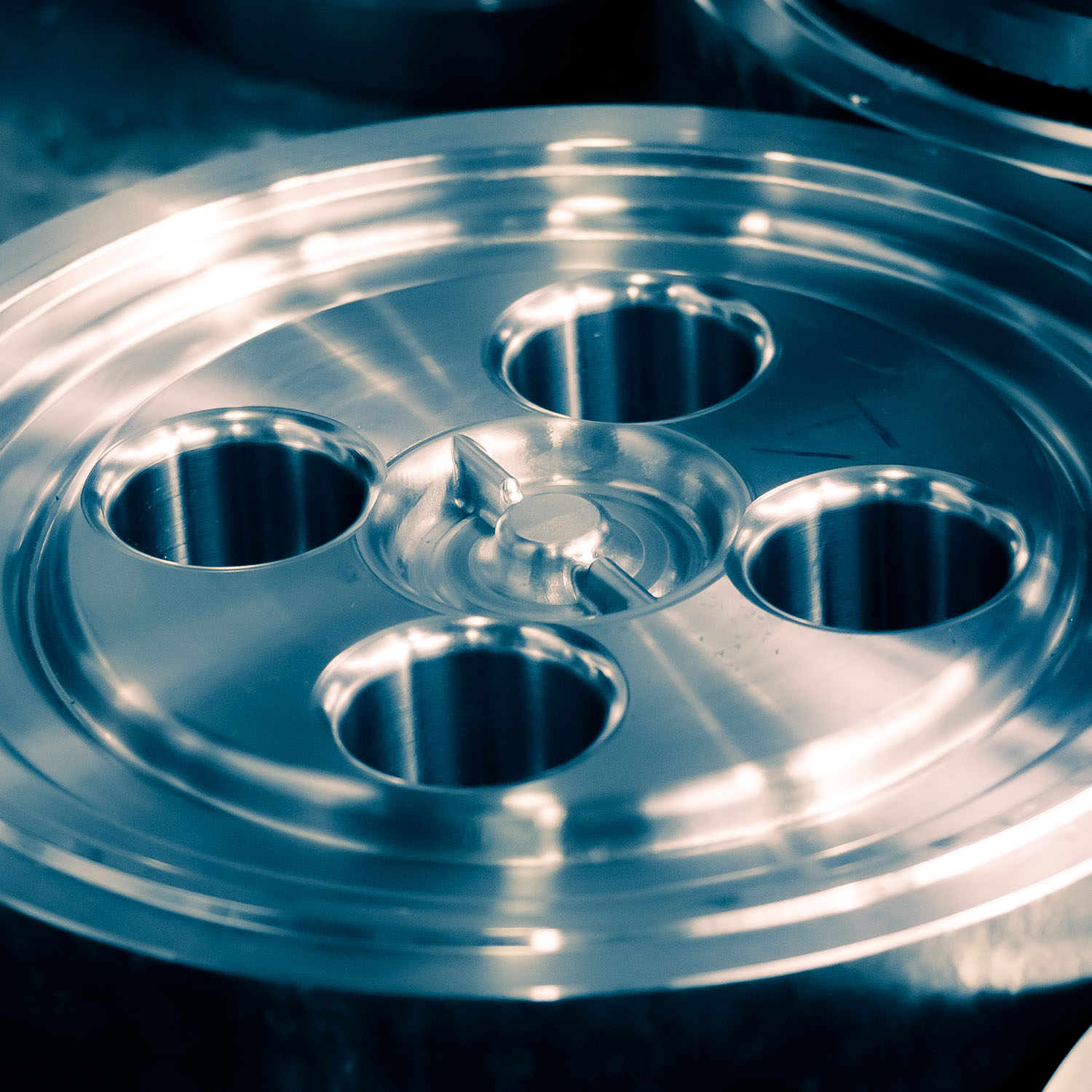

Dies Production

Automated CAM systems with CNC machining centres and lathes

>>>>

Hot Steel Drop Forging

Production lines with induction furnaces, presses, hammers and fly presses

>>>>

Heat Treatment

Fully automated oven lines

>>>>

Precision Machining

Machining and finishing